Market Outline:

CCUS phenomena involves the capturing CO2, usually from large point sources like power generation or industrial facilities that use either fossil fuels or biomass as fuel. This utilized methods such as direct method (i.e. not chemically altered) or indirectly (i.e. transformed) in various products. CO2 today finds its application in fertilizer industry and for enhanced oil recovery.

Opportunity lies in new uses such as producing CO2-based synthetic fuels, chemicals and building aggregates because they are gaining momentum.

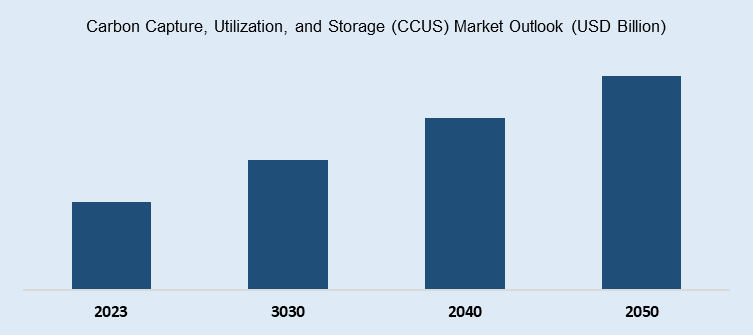

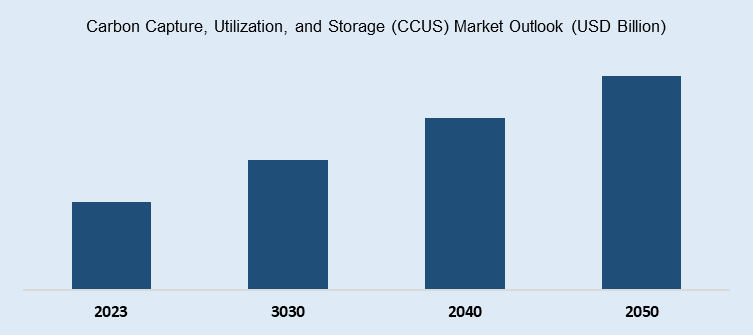

The Global Carbon Capture, Utilization, and Storage (CCUS) Market is expected to offer an $ opportunity of USD 112.1 billion over the analysis period. Market was estimated USD 2.9 billion during estimated year i.e. 2023 and expected to grow at a significant CAGR % over the projected period. And by 2050, the market is expected to touch USD 115 billion market value

Market Segmentation Analysis by:

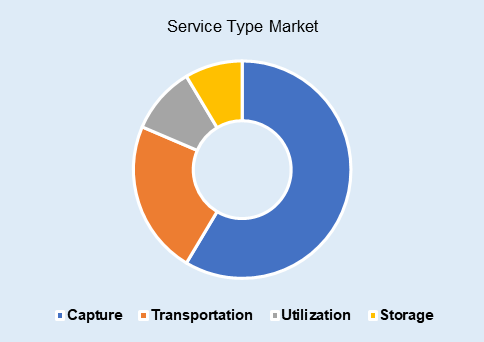

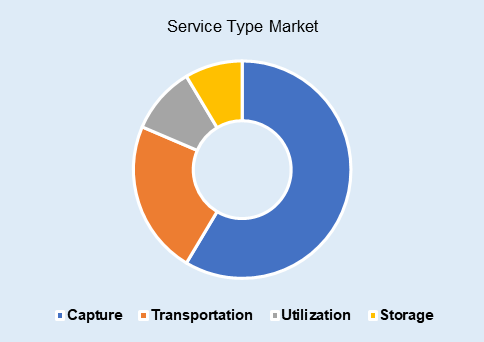

- By Services Type:

- Capture

- Transportation

- Utilization

- Storage

- By Technology:

- Pre-combustion capture

- Oxy-fuel combustion capture

- Post-combustion capture

- By End Use Industry:

- Oil & gas

- Power generation

- Iron & steel

- Chemical & petrochemical

- Cement

- Others

Report Coverage: Report has deeply examined the below pointers:

- Country/regional market attractiveness evaluation

- CO2 emission sources and volume

- Regional level CO2 capturing activities

- Technology installation and infrastructure assessment

- Analysis on government support and policies

- Funding and Investment analysis

- Impact of newly framed policies and regulatory upgradation on market

- Venture capital investment in CCUS projects and companies

- Government funding for CCU companies and commercial projects

- CO2 recovery cost analysis by country

- Application Opportunity Analysis

Market Statistics:

- Global venture capital (VC) investment in 2022, in utilization companies reached approximately USD 500 million, making up nearly 20% of total VC investment in CCUS

- Projects selected for funding under the EU’s Innovation Fund 2021: Carbon2Business project (EUR 110 million); Project Air (EUR 97 million); Hyskies project (EUR 80 million); CO2ncreEAT project (EUR 4 million).

- Government around the globe landing hand for endorsing R&D activities and engineering studies for CO2 mineralisation projects in United states, Australia and Canada.

Technological Landscape:

This part encompasses technologies associated with CO2 separation, conversion and storage.

- Post-combustion CO2 capture and oxy-combustion technology provide retrofit options for existing coal-fired power plants

- Methods currently used or developed for CO2 separation:

- Through physical and chemical solvents, particularly monoethanolamine (MEA)

- Various types of membranes utilization

- Adsorption onto solids

- Cryogenic separation

- Other novel technologies (ionic liquids, Nanoparticle organic hybrid materials, and chemical looping sorbents)

- Integrated carbon capture technologies

- New catalyst technology

- New process technology

- Energy-saving techniques

Market Drivers Examined in Details in Report: Briefly Provided Below

- Sustainable Development Goal Commitment

- Developments and Advancements in CCUS technologies

- Government proactiveness or climate-centric policy

- Financial assistance from leading world institutions

- Surging investment in clean technology

- Rising application of CCUS

Market Trends Assessment:

- Technological Innovations

- Production of Blue hydrogen (H₂), E-fuels Production and Other Useful Chemicals

- CCUS related Infrastructure Development

- Government Policies and Regulatory Environment

- Opportunity Exists for CO2 Utilization

Opportunity Analysis for Market Players:

To address the ongoing challenges associated with CO2 emission, tremendous opportunity lies in the market space for market players. Report section covers the detailed analysis on below opportunities:

- Investing in R&D projects

- Reverse engineering product utilization: Deriving different synthetic gases from CO2 and combined with chemical or biological process, can produce synthetic fuel and basic chemicals.

- High-functional plastics producing from CO2 recovery

- Innovations in the fine chemicals field offer numerous opportunities to make a significant environmental impact

Regional Cost Analysis for CO2 Recovery: Report has addressed the cost analysis pertaining to CO2 recovery across the countries. Report has outlined the impact on overall firm cost after incorporating CO2 capture technology. For instance, incorporating CO2 capture into steel production raises estimated costs by less than 10%, in contrary to hydrogen produced from renewables can raise costs by 35–70%. When compared with conventional production methods.

High cost perhaps is the most cited disadvantage of CCUS. This analysis encompasses technology acquisition, knowledge-transfer, regulatory adherence among others cost associated with the process workflow.

Regional Developments Investigated in the Report:

- Globally in 2022, nearly 50 projects added to global pipeline

- United States has more CCUS projects than any other country

- In Europe, Germany, UK, Netherlands are pondering to develop CCUS in regional industrial clusters

- India has joined hands with various countries such as, France, Germany, Greece, Norway, Romania, Turkey, United Kingdom and United States to achieve laid down objectives.

- For instance, such collaboration reflected in deals, Indo-UK Scoping Reports on Carbon Capture, Utilisation, and Storage (CCUS)

- DST Jointly launches Accelerating CCUS Technologies (ACT) Call

Competitive Landscape:

Players in Market Space - Players explored in the report has been analyzed at various parameters. Analysis done around, established year, offerings, new projects, financial health, market share, collaboration and partnership, patents, funding secures, technology outlook, future strategic move.

Firm aspiring for green innovation:

- Asahi Kasei: It became first organization in the world to commercially manufacture polycarbonate resin from CO2

- MHI Engineering: Company has developed exhaust gas CO₂ recovery equipment for recovering more than 90% of CO₂ from factories and power plants

- Asahi Kasei

- Chevron Corporation

- ExxonMobil Corporation

- Royal Dutch Shell plc

- TotalEnergies SE

- Carbon Recycling International

- CarbonWorks

- Coval Energy

- Electrochaea

- Synhelion

- UP Catalyst

- Mitsubishi Heavy Industries Ltd.

- Air Products and Chemicals Inc.

- Aker Solutions ASA

- Schlumberger Limited